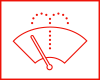

Corner Cut is a technique which creates the perfect intersection at all sharp corners in a single contour, ensuring the ideal cut.

The advantage of Corner Cut explained

Corner Cut applied

A perfect intersection at each sharp corners ensures the perfect contour and easy weeding of the vinyl.

Corner Cut not applied

Every sharp contour in the design is still cut with rounded corners.